Ex SERIES

LIGHTS

LOPOLIGHT PROFESSIONAL Ex SERIES LIGHTS

- WHY EXPLOSION PROOF NAVIGATION LIGHTS?

The location of the Navigation lights onboard leaves little room for flexibility. It is important that your vessel is displaying the correct lights at the correct position demanded by the COLREGS – this enhances safety at sea by lowering the risk for misunderstandings.

APPROVED FOR BOTH IEC Ex/ATEX ZONE 1 AND 2

The Lopolight Professional EX Series is formally approved for use in IEC Ex/ATEX equipment group II, Category 2, Zone 1 (and therefore also Zone 2).

Standards: ISO/IEC 80079-34:2020, IEC 60079-18:2015, IEC 60079-7:2015

IECEx certification from the official authorities.

Lopolight approval certificate (PDF):

P23147I-CC IECEx certificate CNEX 23.0011X

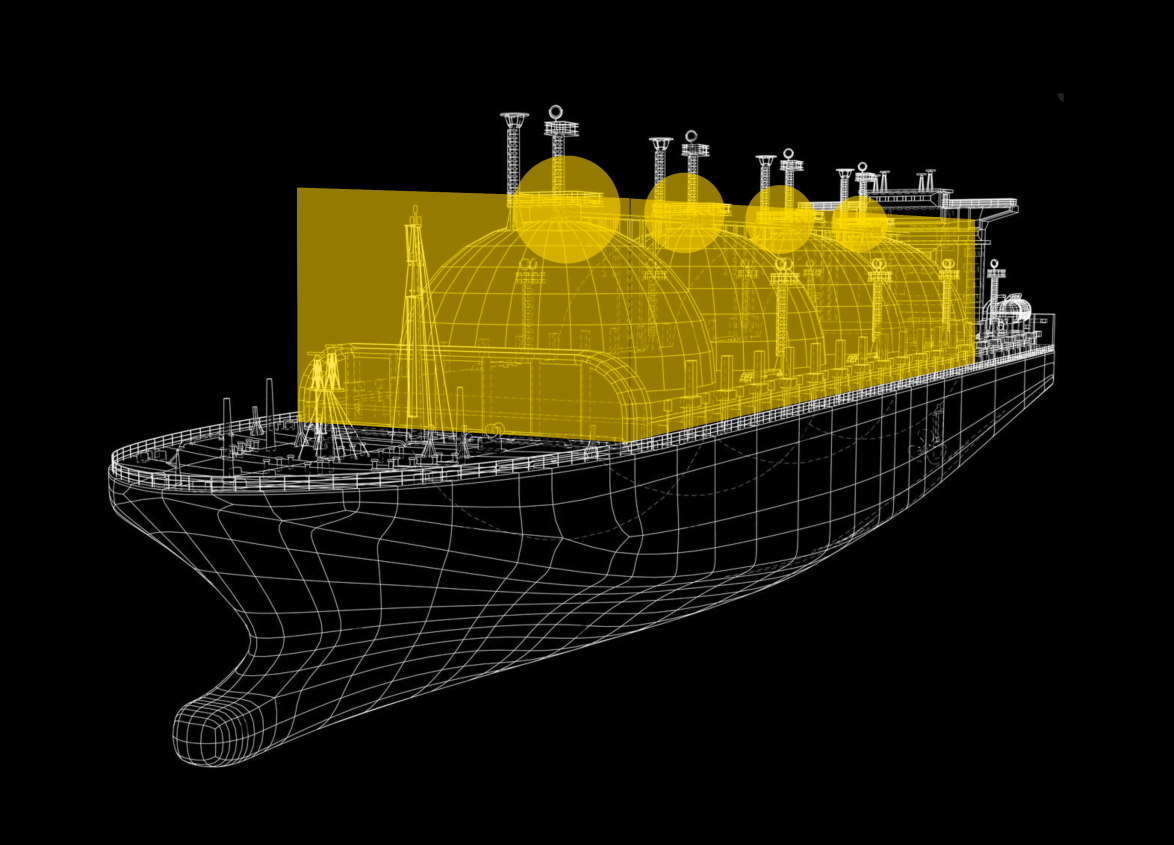

THE NUMBER OF VESSELS WITH AN

IEC EX/ATEX ZONE IS INCREASING RAPIDLY.

Consider the growing fleet of NLG tankers and the associated infrastructure such as tugs, pilot boats and service vessels, or the hundreds of vessels in build now using NLG, Methanol, Ammonia, and others – all with IEC Ex/ATEX zones. And then we have all the oil rigs, with their signal lights.

The full range of the Professional Series are available in the EX configuration – including the ice-class lights!

All in need for no-compromise, rugged, fit ‘n forget light solution.

The EX Series lights are fully compatible with the Lopolight Navigation Light Control & Monitoring system.

ALWAYS SAFE – NOW WE HAVE PROOF

From the first designs 20 years ago – where the electronics of the lights was fully encapsulated in epoxy, power consumption was 1/10 of the comparable incandescent lights, we had a feeling that the product was safe to use in areas where flammable gases could be present.

Immediately after receiving our ISO 9001, quality management certification, which is a pre-requisite for any IEC Ex certification we went to work on getting the Lopolight Professional Series certified for IEC Ex and ATEX.

Labelling/Classification

[Ex]

Explosion protected

[mb]

Encapsulation zone 1

[eb]

Increased safety

[IIB]

Gas group marking

= Ethylene

[T5]

Max surface temp 100 °C

[Gb]

Equipment protection level

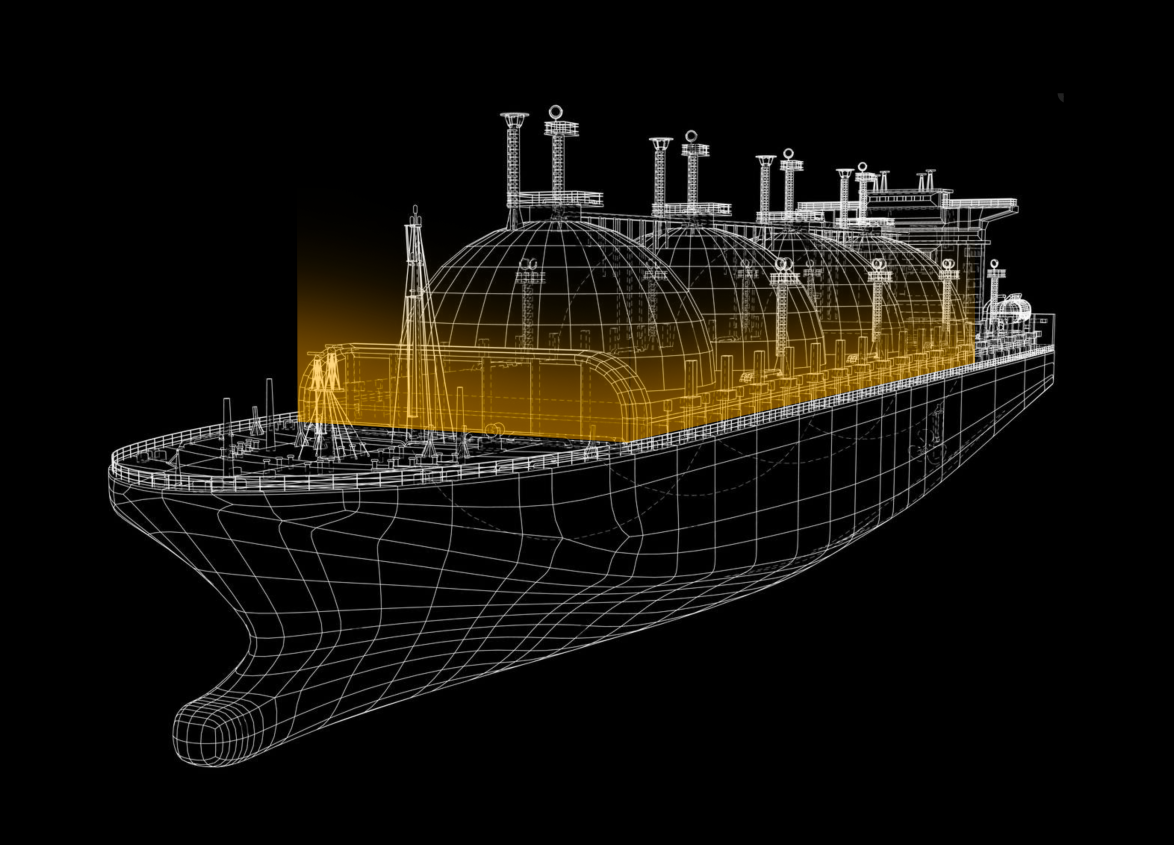

THE DIFFERENCE BETWEEN THE MENTIONED ZONES CAN BE DESCRIBED LIKE THIS:

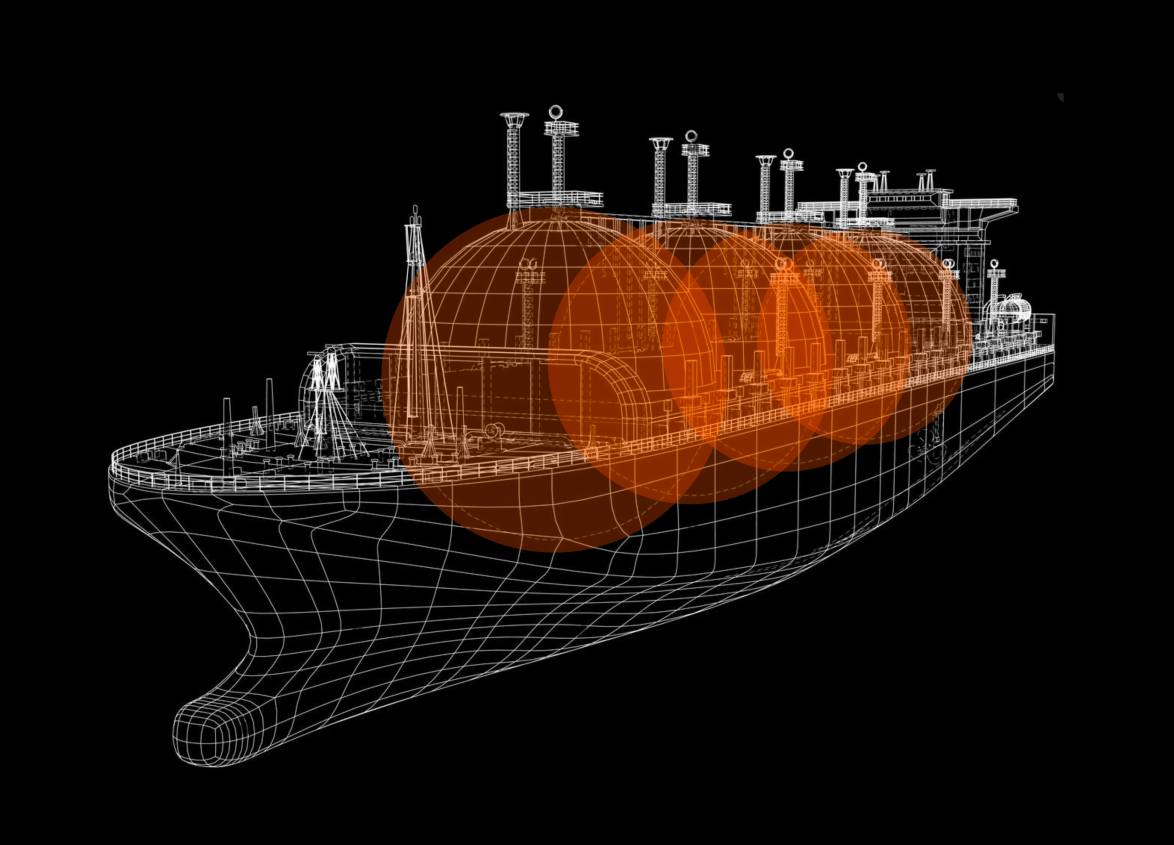

Zone 1 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’, whereas Zone 2 is an area that is classified ‘as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapours and mists is not likely to occur in normal operation but if it does occur, it will be present for a short period of time only’

ZONE 0. ZONE 1. ZONE 2.

ZONE 0: is an area in which an explosive atmosphere is present continuously for long periods of time or will frequently occur.

ZONE 1: Hazardous area is classified as a place in which an explosive atmosphere consisting of a mixture with air or flammable substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally

ZONE 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time.

THE LOPOLIGHT IEC Ex/ATEX SOLUTION

The Professional EX Series lights are kept in the exact same form factor as the regular Professional Series, the difference is in the manufacturing; the use of IEC Ex/ATEX certified components such as connectors and cable glands. The marking is IEC Ex/ATEX specific and there is a grounding strap.